About The R2R NET

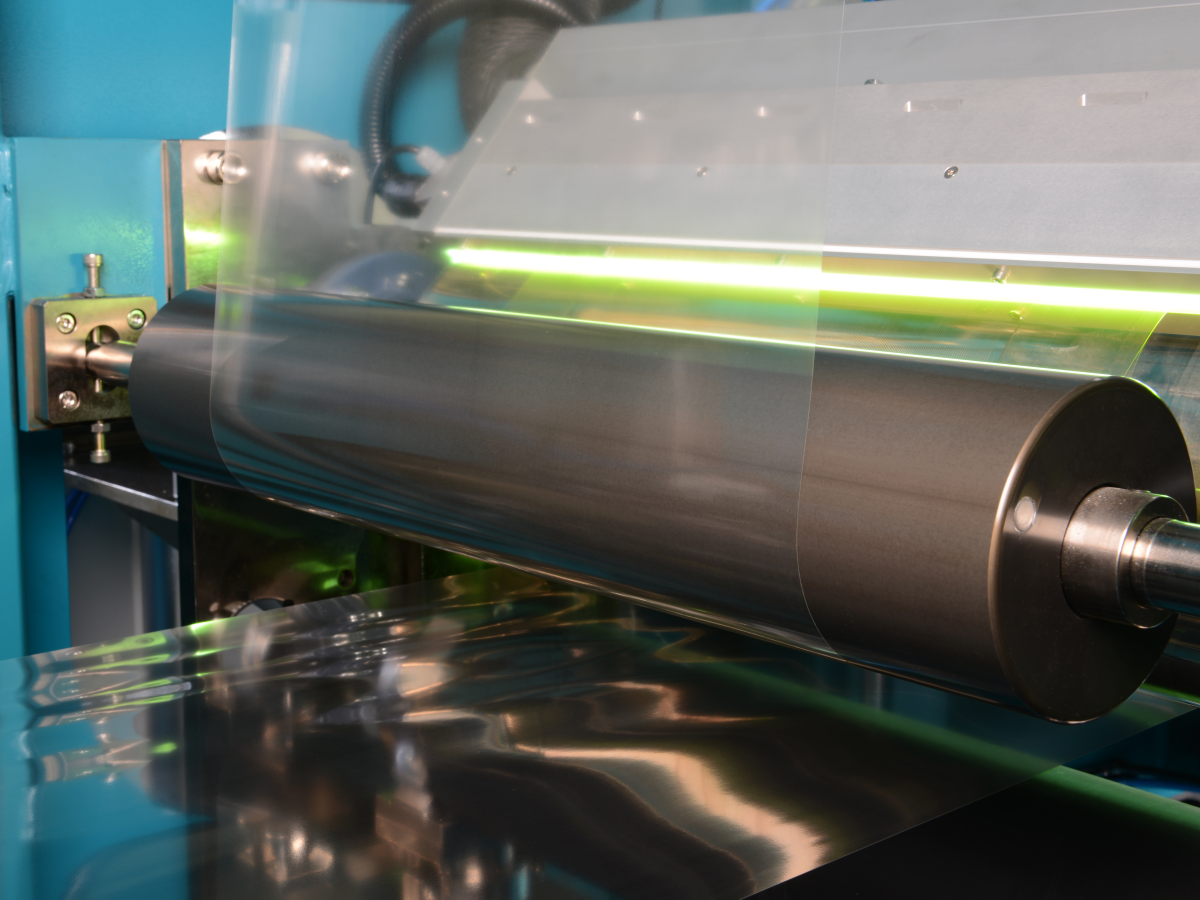

Processing

Objectives

Scope

Opportunities

by the nature of the subject activities are related to

• scale-up of technologies

• prototype production

• equipment manufacturing

• business development

similar technologies for surface functionalization of

• polymer films

• membranes

• textiles

• glass

• metals

various fields of application

connect companies and institutions working in the field of R2R surface functionalization

• companies applying R2R technologies

• equipment manufacturers

• technology providers

• research institutes

• universities

…

support and promote technology

support partners providing their services and expertise

join forces to common challenges (environmental legislation, reduce usage water and energy)

• exchange of information

• promote interaction

• increase awareness about technological options

• support marketing of the partners

• support collaboration

• promote products and technology transfer to the market

• promote joint projects

• join forces towards legislators

scale up from lab to production

• facilities on all levels,

• broad range of technologies

• pilot production with low entrance level

combine technologies

• for the most efficient process

• extend options through the network

learn from other fields

• similar technologies in very different application fields

Membership

R2R Net is open to interested parties. The membership is free of charge.

For application send an informal email to info@r2r-net.eu.

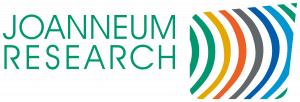

Equipment & Services

overview on offers by the network partners

• machines and equipment

• supplemental materials

• pilot lines

• services

Technical information

Examples for industrial applications of R2R technologies, technical literature, perspectives.

special issue on roll-to-roll processing

- Large-area open air plasma sources for roll-to-roll manufacture: High-power density surface plasma generated by diffuse coplanar surface barrier discharge

- Polymeric substrate properties tailored by irradiation: Roll-to-roll adaptation of mechanical and thermo-mechanical properties of substrates by means of electron beam irradiation at atmospheric pressure

- Roll-to-roll structuring and PECVD coating of polymer foils: Enhancement of hydrophobicity for various applications

- Plasma Nanocoating of Nonwovens: Industrial applications of low pressure plasma technology to boost functional performance of nonwovens

- Flame coatings by CCVD (Pyrosil) for R2R applications: Flame CVD technology and applications for R2R processes

- Advanced Flame Treatment: New opportunities for roll-to-roll functionalization of polymer films

- Ultra-precise surface structuring in nanometer scale: New approaches in diamond turning for manufacturing of asymmetric structures

Newsfeed

Our Network Members

Technical coordinator

Jan Hesse (Fraunhofer FEP, Dresden, Germany)

Board members

Jan Hesse (Fraunhofer FEP, Dresden, Germany)

Dušan Kováčik (Roplas, Modřice, Czech Republik)

Filip Legein (Europlasma, Oudenaarde, Belgium)

Technical implementation

-

Fraunhofer FEP

- Winterbergstr. 28, 01277 Dresden, Germany

- +49 351 2586 351

-

info@r2r-net.eu

Send us a message

Please send us a message with your request